In April 2021 JOST introduced the revolutionary KKS automatic coupling system. It enables the driver to couple and uncouple the semi-trailer via remote control – automatically, safely and quickly. Climbing out of the cabin, cranking down the landing gear and manually connecting the spiral cable, air and brake connections are all a thing of the past. Now JOST presents the latest development of the KKS: the KKSU Connector which is retrofittable to existing trailers that already are on the roads of this world.

Coupling and uncoupling a trailer is still a lengthy, expensive and hazardous procedure. The truck driver has to be aware of many different things, each of which are time-consuming and pose a hazard to health and safety. As the global market leader for fifth wheel couplings and landing gears, JOST is providing a smart solution for the future of coupling with its KKS automatic coupling system. The KKS 42 fifth wheel coupling, Modul E-Drive electric landing gear, sensor coupling system, 3-sensors, LubeTronic automatic lubrication system, KKS remote control and the ISO 13044-2-certified KKS connector all combine to form an innovative system for the coupling process.

KKS-U Connector retrofittable to existing trailers

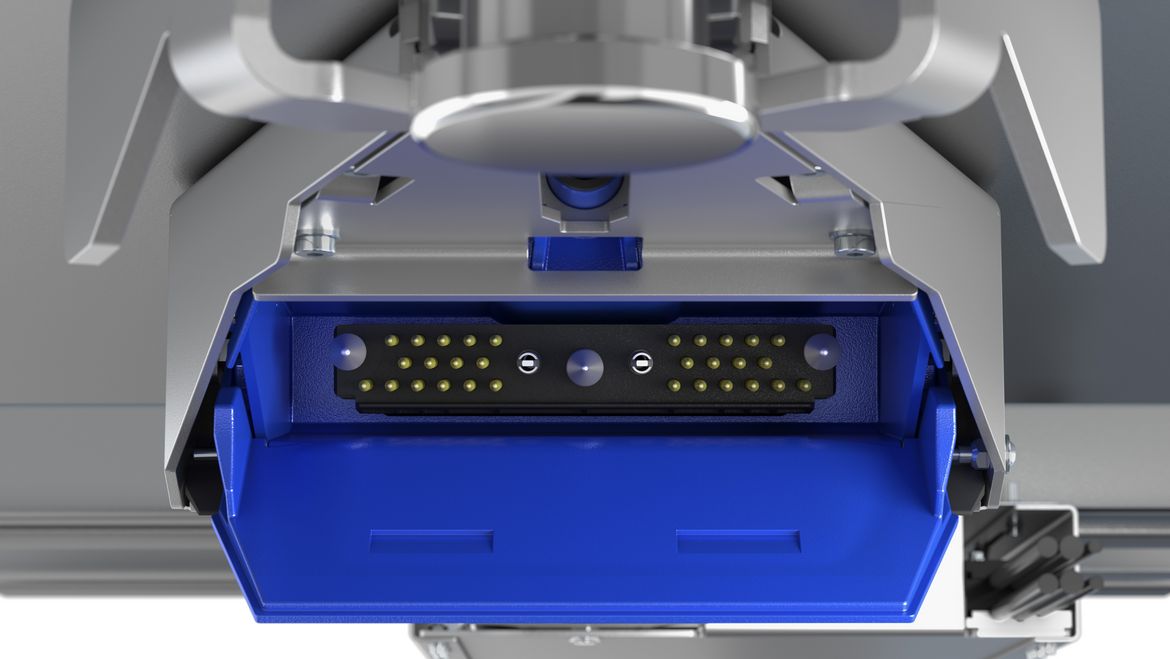

Until now the KKS was a solution for mixed fleets and new trailers. JOST has now further developed the system and is introducing the new KKS-U Connector to the market. Fitted to the underside of the trailer, the KKS-U Connector is an alternative installation variant and enables fleet operators to equip existing trailers easily with the KKS. It connects all the mechanical, electric, and air connections between the truck and trailer, eliminating the need for the standard vulnerable air, electrics and ABS/EBS spiral lines.

The KKS-U basically consists of three parts: the reliable future-proof and ISO 13044-2 compliant standard wedge, the steel spring and the cable box. The newly designed wedge has the familiar KKS connector installed inside. It is attached to the high-quality JOST king pin and rotates around it when cornering. The steel spring encases the supply lines for air, brake and electric safely and reliably. The supply lines are safely stowed in the KKS cable box and are fed into the steel spring when cornering.

“The KKS-U Connector is a unique solution for all trailers that are already in operation. Due to a particularly straightforward installation, they can be effortlessly equipped with the KKS system. No modifications to the trailer chassis are necessary”, said Andreas Jakubin, Product Manager KKS. “Thus, the KKS-U contributes to further savings in time and expenses as well as avoidance of accidents.”

Advantages of the KKS: more efficiency and safety for truck drivers

Using the KKS automatic coupling system can cut the time required to change a trailer by up to 50 percent, as there is no need to manually crank the landing gear, connect the supply lines or open the fifth wheel coupling. The KKS significantly reduces the total costs for each circuit, with savings of up to 50 percent possible during the coupling and uncoupling process. It is particularly well suited for transport companies which perform coupling processes often and drive short distances, such as those in on-site transport, as the time saved here really pays off financially. Another application is the transport of goods where safety plays a key role, such as hazardous goods, as the sensor monitoring guarantees a high level of security against trailer losses and incorrect coupling. The KKS is also an ideal solution for transport between production sites and logistics facilities. Errors or damage caused during the coupling process are eliminated completely thanks to monitoring through the KKS remote control. For example, the Modul E-Drive landing gear is always fully retracted automatically. Moreover, the KKS reduces the probability of trailer losses due to erroneous operation, damage and occupational accidents to virtually zero.

Furthermore, the KKS makes all the physically demanding tasks of the coupling process a thing of the past, as well as ensuring that this process is no longer dependent on the weather or time of day and significantly reducing stress. A standard pneumatic cylinder opens the fifth wheel coupling effortlessly, even when the tractor-trailer is twisted. The automatic coupling process means that the driver does not have to climb in and out of the cab as often, nor climb onto the catwalk between truck and semi-trailer – two factors that significantly reduce the potential for injury. These benefits mean the KKS opens new possibilities for a more diverse driver pool; as such, JOST is providing an answer to demographic change and the lack of specialist workers.

More information on the KKS and KKS-U Connector online at: kks-futurenow.com