Visitors of the Agritechnica can see these forward-looking technologies for agriculture:

Quicke

- Powergrab M+/L+/XL+

- Multigrab M+

- Q9S

- Quicke Control System – QCS

- Q-companion

ROCKINGER

- RO845D automatic 50mm hitch with camera system & pneumatic

- RO841B automatic 40mm hitch with camera system & pneumatic

- Low-maintenance calotte KS80 with wear insert

- 80mm ball hitch KS80 with safety sensor

- Three-point linkages

Quicke innovations

Three new bucket grabs get it done: Quicke Powergrab M+/L+/XL+

Quicke is expanding the successful Powergrab series with the Powergrab L+ variants for loaders with a lift capacity of up to 5.5 tonnes and Powergrab XL+ for loaders with a lift capacity of up to 10 tonnes. Both newcomers are designed as powerful bucket grabs for silage handling with large front loaders, telescopic handlers and wheel loaders. As highly efficient tools for silage removal, the new Powergrab models are ideally suited to farms with high feed rates. Their cylinders can handle all types of silage –grass and corn silage, loose feed and liquids. The first-class workmanship is extremely robust – The well-proven design minimises disruptions to productivity and creates reassuring reliability. In addition, there is a cut-out in the grabber that also enables use on loaders with Z-link kinematics - making the new Powergrab versions a particularly attractive solution for a wide range of customers. Both Powergrab L+ and XL+ are available with the M24 bolt-on hook-system, which allows them to be used with all common loading machines. With the Powergrab L+ and Powergrab XL+, the Swedish agricultural machinery specialists are particularly addressing farmers who have high power requirements and want to operate with extra efficiency. The new Powergrab models support a particularly high silage removal frequency, minimise silage losses and are specially designed for long-term high-performance use.

The third and youngest of the bucket grabs is the Powergrab M+, which fills the gap for silage handling with medium-sized handlers in the Powergrab range. Powergrab M+ is designed for use with front loaders, compact wheel loaders and up to medium-sized telehandlers.

Multi-functional bucket with top grab: the clever Multigrab M+

The Multigrab M+ is the ideal solution for handling solid manure, silage and waste. The intelligent basic concept of the multi-functional bucket grab and clever accessories take farming to the next level. The Multigrab M+ is designed for use with front loaders, compact wheel loaders and up to medium-sized telescopic loaders.

A new member for the premium Q Series front loader: the Q9S

The new Quicke Q9S loader is specifically dedicated for tractors from 160 hp to 300 hp. Enlarged loader width of 1 420 mm allows fitting this loader on tractors with large bonnets and ensure enough space for maintenance. It also provides excellent visibility and perfect match with nowadays tractor bonnet using loader arm curved shape. The Quicke Q9S adopts mechanical self-levelling solution that provides simplicity, reliability and increased lifting force compared to loaders without mechanical self levelling. Quicke Q9S has been designed to handle tasks which needs high lifting height and lifting capacity. This makes the Quicke Q9S able to handle with a wide variety of heavy tasks performed within professional farms. Smart features embedded on Quicke Q9S ensures the expected reliability for such handling machines. State-of-the-art options such as the Q-Companion weighing system and the optionally available driving assistance take the farmer to the next step of digital and connected farming.

Quicke Control System – QCS: robust controls for Smart Farming

Years of field testing and experience in developing innovations are the building blocks of the QCS intelligent control system. The QCS program includes joysticks, valves and multi-couplings: from the simple and cost-effective mechanical loader control QM-command to the ergonomic all-in-one QE-command, the new electronic joystick. Robustness, performance and user-friendliness are the focus of the loader controls. The Quicke system simplifies all front loader tasks to the maximum. Whether harvesting, clearing fields, feeding livestock or fast data collection and cloud transfer: The QCS automates repetitive tasks and material weighing and optimises implement settings individually. The simple joystick operation relieves the farmer to the maximum. This is smart farming at the touch of a finger.

ROCKINGER innovations

RO845D automatic 50mm hitch with camera system & RO841B automatic 40mm hitch with camera system

Because millimetres matter, reversing and coupling can be a challenge even for experienced drivers with a standard trailer hitch. The ROCKINGER RO845D hitch is the first automatic 50mm trailer hitch with an integrated camera system that solves exactly this problem. The calibrated camera system detects the drawbar eye and gives the user a spatial orientation during the coupling process. With the help of the crosshairs, the towing eye can be aligned and the centre of the trailer can be approached. In addition, the area for the optimum height of the vehicle to the towing eye is displayed with the aid of the green guide lines, which in total means a significant increase in driving comfort as well as the level of safety.

The automatic 40 mm hitch with RO841B camera system also enables a more efficient and safer hitching process. In addition, the optional pneumatic remote control supports the opening and closing of the hitch powerfully and comfortably. The farmer can operate the camera systems intuitively. They help him to avoid accidents and damage.

Less grease and less wear thanks to the low-maintenance calotte

The lubrication of a KS80 ball hitch is necessary, but grease magically attracts dirt, which in turn leads to higher wear. By using the ROCKINGER calottes with wear insert, no further lubrication is necessary. This results in less wear on the KS80 ball and saves up to eight cartridges of grease per cap per year. The insert eliminates the need for lubrication and prevents high costs for regeneration of the coupling. For maintenance, the ball and draw cup only need to be checked with a gauge. ROCKINGER recommends changing the wear insert once per season. This makes the KS80 a sustainable, environmentally friendly and cost-effective solution.

KS80 ball hitch with safety sensor provides extra safety, comfort and sustainability

Anyone who has ever used a KS80 ball hitch knows that in rare cases it may not be properly locked. This danger can result in accidents. The ROCKINGER KS80 ball hitch with safety sensor shows the correct locking status of the hold-down device of the KS80 ball hitch on the display in the driver’s cab. Incorrect operation and resulting damage to the KS80 coupling, the towing vehicle and/or loss of the trailer are ruled out. The system operates completely wirelessly, including a dirt- and waterproof unit (IP-69-K). The versions currently still in the prototype phase are suitable for heavy-duty use with 4 t drawbar load and a D-value of up to 130 kN.

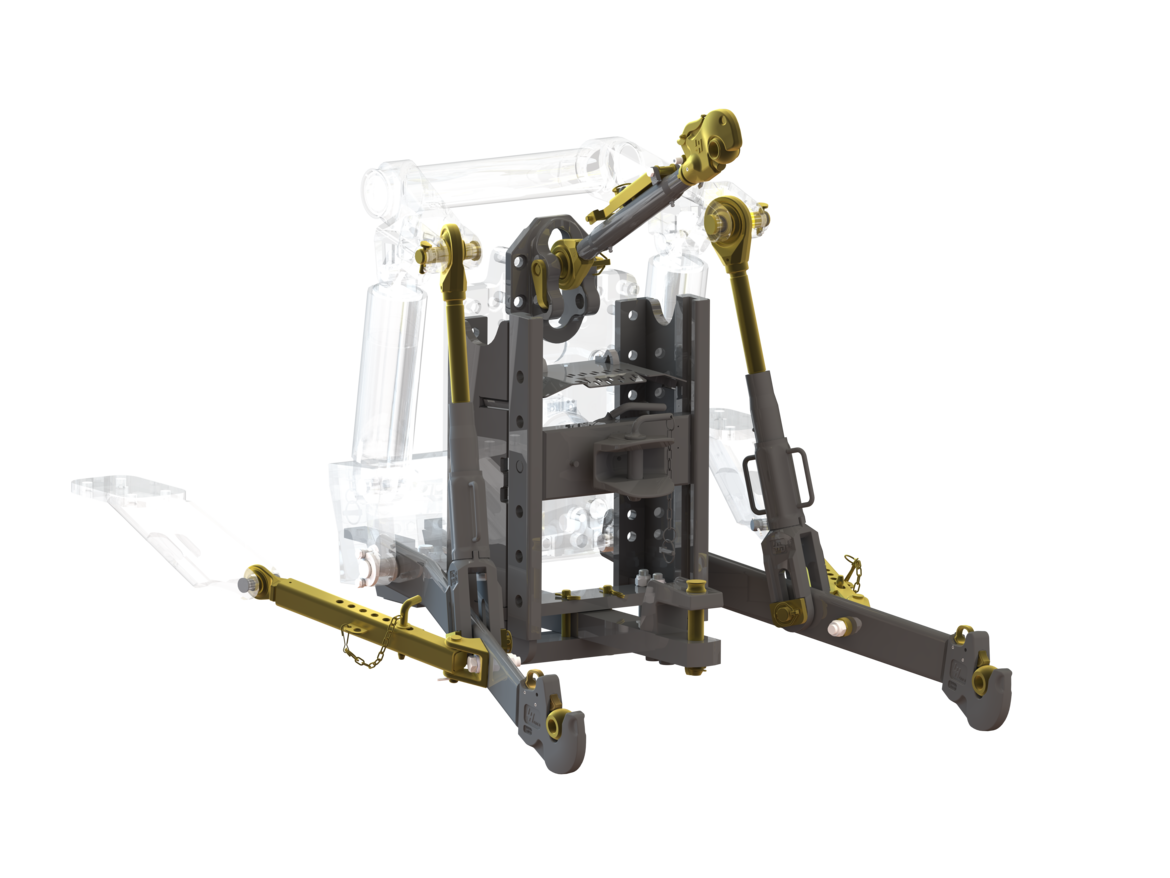

Three-point linkages

ROCKINGER will also be presenting three-point linkages for the first time at Agritechnica. In this year's integration of LH Lift, an established Finnish supplier and manufacturer of three-point linkages and hitches for agricultural tractors, the product portfolio will be expanded to include lower link arms, top links, stabilisers, lift rods and quick coupler hooks.

JOST Agriculture stand: hall 6 / stand C15